Dennis is a hard-working business professional who enjoys spending time with his family and friends. He likes to stay active, and loves playing sports. Stephanie is always looking for new challenges and opportunities to grow both personally and professionally.

In plastic recycling plants and factories, plastic shredders serve an essential function. It provides several advantages as a byproduct of processing plastics, which are used to make things like storage containers, toys, packaging bags, and consumer electronics. Industrial plastic bottle shredder help recycle plastic scraps of all sizes.

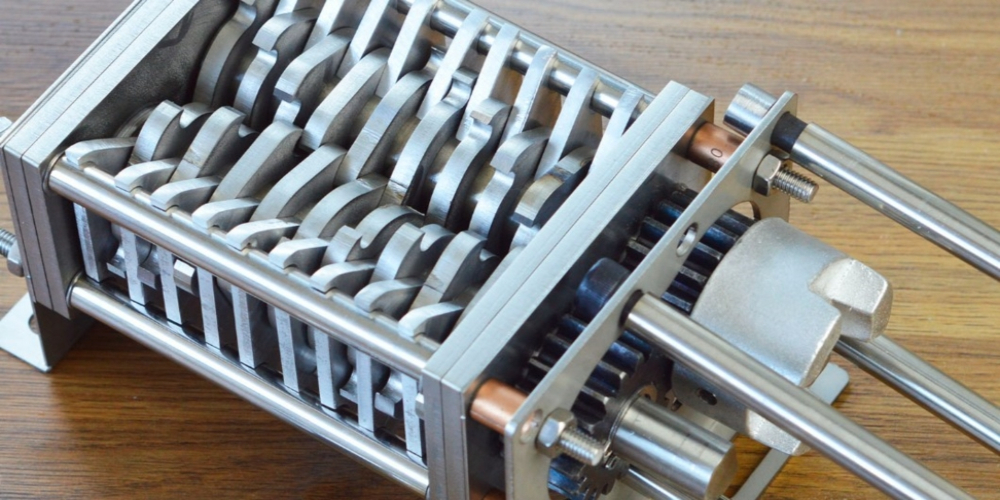

Strong and sturdy construction

Recycling and trash management can only function efficiently and cheaply with shredders. Because of the extensive range of plastics that need to be shredded, plastic shredders come in a wide array of speeds, torques, blade diameters, and other configurations.

Plastic shredders come in various models and types, from simple one-shaft machines to complex four-shaft mechanisms with grinding, granulating, hammering, cutting, sorting, and shaking capabilities. Their main characteristics are:

Possibility to automatically go backward

Intricate size and form modification using cutting-edge personalization techniques. Plastic shredders can be found in many different settings, such as factories, hospitals, nursing homes, healthcare facilities, cardboard factories, and supermarkets.

Plastic shredders have several applications in waste management. Plastic shredders reclaim scrap from various manufacturing procedures, including molding, trimming, and casting. Trash that has been shredded can be more easily recycled or disposed of. In addition to being an effective trash disposal option, shredding helps various sectors save money on recycling. Businesses that sell shredded plastic for manufacturing purposes also use plastic shredders as a source of income.

They recycle plastic to be used again in making new items out of plastic, PET bottles, and PVC. Moreover, they aid in the recovery of garbage dumped by businesses. Shredding sensitive business documents, CDs, and floppies can be done with a plastic shredder to keep private information private. Enterprises may save the planet and lessen their impact on the climate by recycling and reusing plastic scraps.

Why Businesses Should Recycle Plastic Using Shredders

No matter the size or shape of the plastic, a plastic shredder is an efficient and effective way to transform waste into valuable resources. Working with plastics, vinyl, and PVC pipes requires a shredder. Plastic can be broken down and reused as a raw material for other things. It is crucial to select a machine that combines usability with the performance you require if you want to guarantee efficient and high-quality plastic shredding.

There are a variety of industrial shredders suitable for plastic shredding, each optimized for a particular size and type of plastic debris. A plastic shredder’s internal mechanism can move laterally, vertically, or rotatively and its speed can change based on the type of plastic being shredded. Shredders made of plastic can be broken down into six distinct varieties, each serving a different purpose in manufacturing.

Conclusion

Plastic waste from manufacturing operations can be recycled via granulators. Thermoforming devices are included in most granulators, allowing for the creation of a convenient scrap for handling. In addition to being environmentally benign, industrial shredders save money on hauling fees and time compared to traditional waste disposal methods like incineration. Plastic shredders are one option for firms interested in eco-friendly plastic disposal, but industrial garbage compactors or balers are other viable options for productive and low-cost recycling.